Recovery & Reprocessing of Lithium Bromide Solution

Onsite Recovery & Buyback of Lithium Bromide Solution

We are one of the few companies that can function nationwide and recover and recycle & buyback Lithium Bromide (Libr) solutions from an Absorption Chiller. If you are decommissioning an old chiller or just replacing the fluid we are able to fully drain it including removal scale & sludge. The scale and sludge will be safely and legally disposed of. We have worked on Carrier, Trane, York, Broad, Panasonic, Mitsubishi, Thermax and Yazaki Absorption Chillers. We are capable and have at some types of had to "Hot Tap" some chillers to drain in several locations to bypass crystallization and scale buildup to effectively fully drain some chillers. We are able to dewater & purify Lithium Bromide by centrifuge and resell the purified Lithium Bromide directly back to Primary Lithium Producers & Refiners.

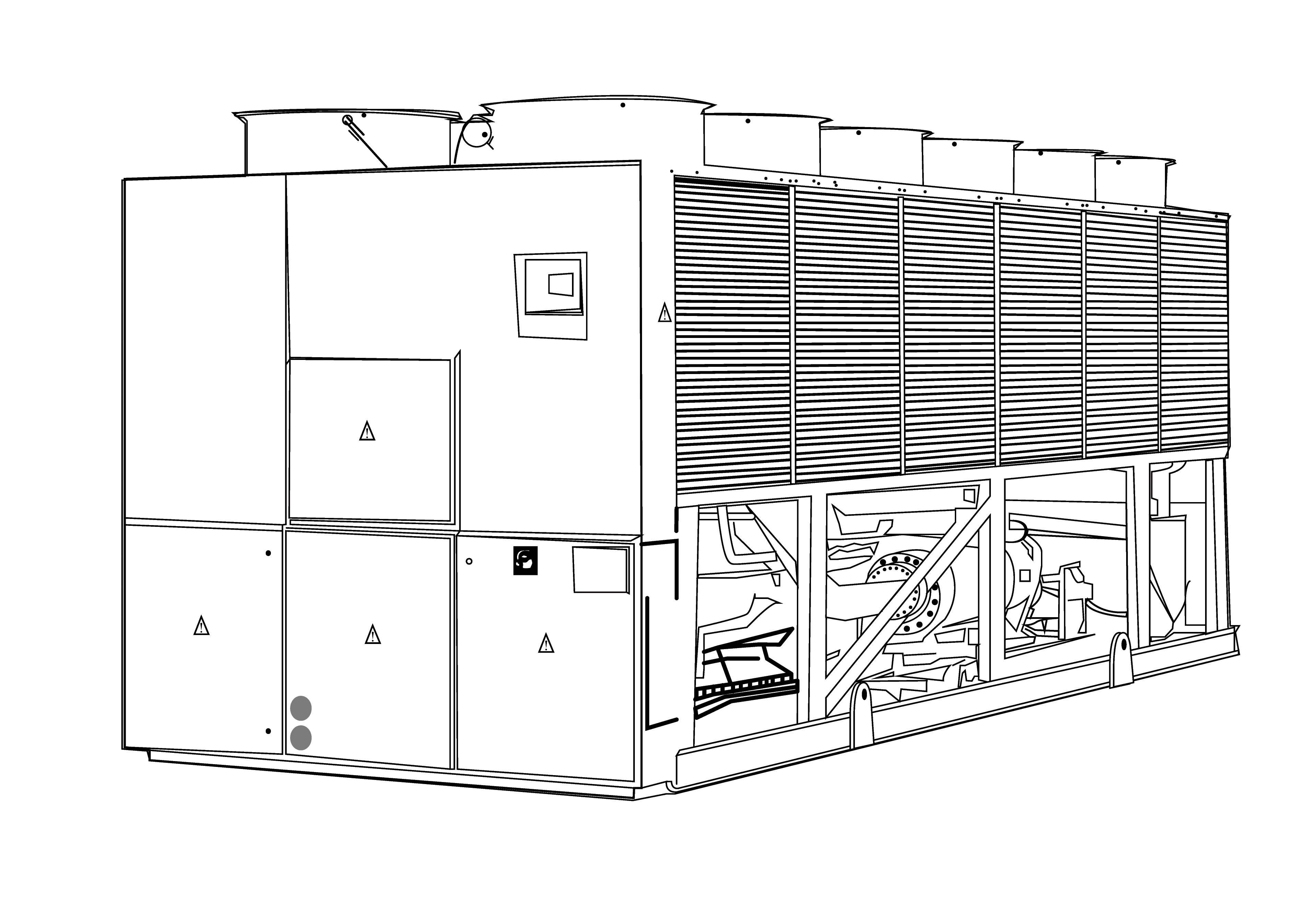

Large Tonnage Absorption Chillers are highly efficient chemical chambers that can cool massive buildings and campuses even entire cities very economically. This is because they have almost no moving parts and are essentially powered by heat and chemical reaction and not electrically driven compressors. The problem with these chillers is that the chemical refrigerant that supports them is highly corrosive to the steel that they are made from. This chemical solution is Lithium Bromide. As a chiller corrodes the steel that the chiller is constructed of begins to flake and delaminate it generates large quantities of abrasive particles that clog the chiller and it's nozzles and chambers hampering the chemical process that generates cooling.

To prevent corrosion these chillers are kept as a closed loop system to prevent oxygen from entering the chiller promoting corrosion and chiller deterioration. Since rust corrosion of iron and copper is also known as oxidation, no oxidation can occur if oxygen is kept from entering the system. However with the stress on facilities maintenance personnel it is almost impossible to detect and prevent every air leak in these systems. To prevent deterioration of these chillers technicians have developed several tricks of the trade. One is to introduce chemical additives to the solution, these are known as inhibitors. These inhibitors do inhibit corrosion to steel but they change the Lithium Bromide solution into hazardous waste.

These massive chillers are primarily made from 2 metals, steel and copper and copper based alloys. While these additives will inhibit the corrosion of steel some of them promote the corrosion of copper. So one metal is sacrificed for another both lead to the deterioration of the chiller. Another trick of the trade is to attach a vacuum pump to the chiller's purge system. This will increase an absorption chillers efficiency because the chemical process is performed in a vacuum. Under some conditions keeping the interior of a chiller in vacuum hinders the corrosion process. But if the system has a large air leak the corrosion process will accelerate. With these systems so suseptable to corrosion many facilities have sought to decommission or retire these chillers early and replace them.

If you are decommissioning your Absorption Chiller we can recycle your Lithium Bromide Solution. If an inhibitor such as Hexavalent Chromium has been added it's profile will change and be reclassified as hazardous. We are capable of safe and legal disposal of Lithium Bromide Waste solution that has been classified as HazMat. as If your Lithium Bromide solution is Hazmat we can offer some of the lowest disposal rates in the USA. Lithium Bromide solution itself is not classified as hazardous waste by the EPA. It is however an irritant to the skin and mucous membranes. If it is vaporized and inhaled it can cause lung damage. Depending on a technicians sensitivities we have seen Lithium Bromide solutions stain skin on arms and legs for decades. These stains may be classified as painless chemical burns. All one has to do is witness the damage done to leather gloves and shoes by these solutions. Technicians have had to throw away leather boots after just a few minutes exposure. As one watches his shoes instantly curl up one wonders what could be happening to skin and lung walls. We have seen especially sensitive technicians incapacitated for days because non-hazardous Lithium Bromide solution has spilled on their skin.

We have a specially trained field service team that can come to your site and sample and lab test & analyze and provide you a profile of your solution. We can thenpump down and containerize and remove your old solution. Our technicians are specially trained and equipped to handle Lithium Bromide solutions. We can also decontaminate your chiller for recycling purposes. Even if an absorption chiller has been dehydrated if the solution has been inhibited by Hex-Chrome it should be decontaminated before being recycled. We can dehydrate and decontaminate your chiller and make it ready for recycling. We also offer in place recycling of your Absorption Chiller. We can drain it, dehydrate it, decontaminate it and cut it into 30 lb pieces and remove it from almost any location in a building without demolition of your building walls, floors or ceilings. We have removed chillers from 30 Stories up in a penthouse and 80 feet underground in sub basements. Even carrying chillers that weigh 60,000lbs through piece by piece through narrow doorways and down staircases.

If you have dehydrated your absorber of Lithium Bromide solution if it had an inhibitor we can profile your solution and provide you a detailed analysis to determine the cause of failure and also for disposal and hazmat hauling purposes. Some of the Chemical additives that are known inhibitors of Absorber Corrosion are:

hydrobromic acid lithium arsenate lithium chromate lithium molybdate lithium nitrate

These chemical additives can instantly change the profile of your lithium bromide solution to hazardous waste. Special permits are required to haul it and it must be tested and profiled before being disposed of. We have contracted with several municipal wastewater treatment plants to remove metals such as lithium, molybdenum, chromium, iron and copper from solutions through precipitation and reduction. In most cases these wastewater treatment plants utilize carbon columns for treatment of these solutions.In some cases such as with molybdenum these metals are easily recycled after processing.

UPE Company (Utility Plant Equipment)

32501 Gordon Side Road Building I

Fulshear, Texas 77441

(346) 402-0400

Email: buying.manager@upecomp.com

Eastern Office :

(484) 519-7305

Allentown, Pa.

email: east@upecomp.com

Western Office :

(209) 601-7833

Manteca, California

email: west@upecomp.com

© Copyright Utility Plant Equipment